Programmable

feeders

Inspection

systems

Vibratory

feeders

Part Families

Bulk

feeders

Other

products

Home

Contact

us |

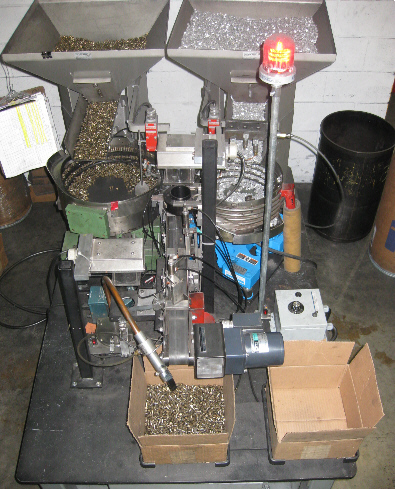

POSI inspection

systems

are custom systems for inspecting

parts for any type of defect that can be detected visually.

All systems are designed using high

quality

machine vision cameras. The design

philosophy is “if there is any question, reject the part”. In

keeping with this philosophy the systems

are designed to require a positive action to accept a part. Thus

if there are any failures anywhere in the

system no bad parts could be accidentally accepted.

These

systems, like POSI

programmable feeders, can be designed

to accommodate a range of parts. The

system configuration is dependent upon the parts to be inspected, the

inspection requirements, the desired inspection rate and other customer

requirements. In

situations where multiple surfaces are to

be inspected, the inspection rate determines the number of cameras

required. For high rates one camera is

typically used

for each surface; however, for low inspection rates one camera may be

able to

inspect multiple surfaces.

POSI inspection

systems typically use a bowl feeder to

orient or partially orient the parts to be inspected. The parts

are then fed to an inspection fixture, gripper, or on to a conveyor at

a

controlled interval. In the case of a conveyor, the conveyor

carries the parts past a camera where the first inspection is

done.

If the part fails it continues along the

conveyor to a reject discharge. If it

passes the first inspection, it is shifted to the good discharge.

At this point it either proceeds to the next

inspection in the case of multiple inspections or, in the case of a

single

inspection, to the system good discharge. In low inspection rate

situations the entire

inspection can be done at

the bowl discharge.

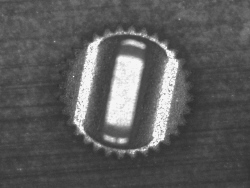

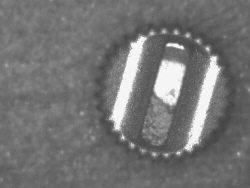

The system

shown inspects two different

cylindrical

parts in a dirty environment . The first part, shown with a penny for size

comparison, is checked for broken or chipped tabs. Inspection of

the other end of this part is not required consequently only the first

camera is

used.

FIRST PART

|

GOOD PART

|

REJECT--CHIPPED

TAB

|

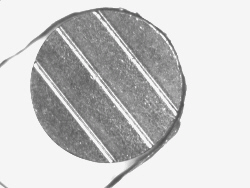

The second part

requires inspection of both ends. The first camera rejects any

parts with broken or chipped legs. Parts with good legs are

flipped over and proceed to a rotating wheel with slotted cavities for

the parts.

SECOND PART

|

GOOD FIRST END

|

REJECT--BROKEN

LEG

|

The rotating wheel carries the parts under a second camera where the

teeth on the second end of the part are inspected. In this case,

parts with chipped teeth are evaluated in terms of the size and

location of the chips to determine if they are acceptable or not.

GOOD PART

|

ACCEPTABLE PART

|

REJECT--LARGE

CHIP

|

The

inspection rate for either part is 4000 per hour. Switching

between parts is accomplished via a

selector switch. The good parts are

counted into a shipping box. When the

required number of good parts have been placed in the box, the next box

is

shifted into place.

|