Bulk Feeders

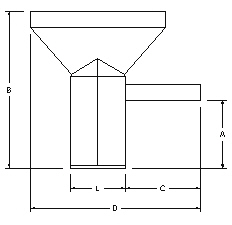

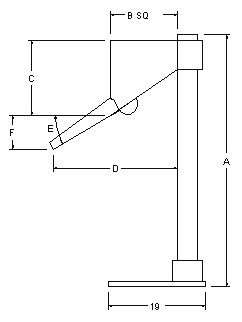

Loaders POSI offers a wide variety of loaders to supply parts to your elevated parts feeders. These units incorporate a hopper, a cleated belt elevator, and a level control sensor to allow parts to be dumped into the hopper at floor level while maintaining the desired level of parts in an elevated parts feeder. Hoppers can be supplied in mild steel or stainless steel with capacities ranging from 5 to 20 cubic feet. A variety of belt elevators are available with discharge heights ranging from 3 feet to 11 feet. PROGRAMMABLE ORIENTING

SYSTEMS, INC.

1547 Sartwell Creek Road FAX (814) 544-4000 Port Allegany, PA 16743 Sales@posifeeders.com (814) 544-4000  |