Programmable

feeders

Inspection

systems

Vibratory

feeders

Part Families

Bulk

feeders

Other

products

Home

Contact

us |

What are

POSI

programmable feeders?

Unlike hard

tooled

feeders, POSI

programmable

feeders can be designed to orient a wide range of parts with one

feeder.

The versatility and rapid changeover provided by these feeders make

them

ideal for flexible manufacturing where a number of traditional parts

feeders

might be required or where the volume of any one part might not justify

the use of a parts feeder. They are also well suited to mass

production

where a change in the parts being fed can be readily accommodated.

POSI

programmable

feeder concept

POSI

programmable feeders

are designed, using standard programmable tooling modules, to feed a

particular family of parts -- as

defined by

the customer. The part family

and

the required feed rate determine the size and type of feeder to be used

i.e. vibratory feeder with cascade bowl, vibratory feeder with an

outside

track bowl, or a rotary orienting feeder. The part family and the

desired orientation determine the family of programmable feeder i.e.

Model

I, Model II, or Model III.

Model

I

family of programmable

feeders Model

I

family of programmable

feeders

POSI

programmable

feeders that are tooled without vision systems are members of the Model

I family. These units only use programmable or adjustable

mechanical

tooling modules. Although much less sophisticated than the other

models of programmable feeders, these units are well suited to

orienting

simple parts such as headed parts and parts that have no end-to-end or

side-to-side differences.

Changeover

of

the feeder

for a different part is just a matter of programming the mechanical

tooling

modules, a process that typically only requires a couple of minutes.

|

Model

II

family of programmable

feeders

POSI

programmable feeders that use a camera or vision sensor as part of

the

bowl tooling are members of the Model II family. The additon of a

vision system provides the flexibility to handle a wide

range of

parts

in a bowl and allows orientation of parts that would be extremely

difficult, if not impossible, to orient with conventional mechanical

tooling. POSI

programmable feeders that use a camera or vision sensor as part of

the

bowl tooling are members of the Model II family. The additon of a

vision system provides the flexibility to handle a wide

range of

parts

in a bowl and allows orientation of parts that would be extremely

difficult, if not impossible, to orient with conventional mechanical

tooling.

These units

may employ programmable mechanical tooling modules or they

may use conventional tooling to pre-orient the parts for the vision

system. The vision system is positioned in a location where the

mechanical tooling elements have

ensured

that the parts passing it will be one high and one wide. The

vision sytem

monitors the flow of parts to determine if each part is the desired

part

in the desired orientation. In the simplest implementation

incorrect

parts and incorrectly oriented parts are rejected back into the

feeder.

Only the desired part in the desired orientation is allowed to continue

to the feeder discharge.

Programming

a

Model II feeder

for a different part is simply a matter of programming the mechanical

tooling

modules and the vision system -- a process that can usually be

accomplished in a

few minutes.

|

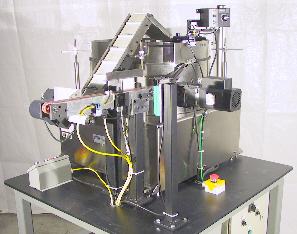

Model III

family of

programmable feeders

Model

III

programmable feeders

use a conveyor to carry parts past the vision system. This

configuration can provide more flexibility in positioning the camera,

more lighting options, better part separation, and higher feed rates.

Model III

feeders typically

include a conventional or Model I rotary or vibratory bowl feeder

which is used to feed

parts one high and one wide on to the conveyor. In its simplest

implementation good parts in the desired orientation are allowed to

pass to the end of the conveyor while bad parts or parts in the wrong

orientation are returned to the bowl feeder via the return conveyor.

Programming

the

camera can

be as simple as showing the camera the part in the desired orientation.

Programming

the

entire Model

III system typical only requires a couple of minutes.

Feed

rates of

several hundred

parts per minute are possible.

|

|